Echo 声波移液系统

Echo 声波移液系统 是一款先进的实验室自动化仪器,采用非接触式声波移液技术,移液体积低至 2.5 nL,支持任意孔间纳升级液体精准移液,提供卓越的移液灵活性及优异的准确性和精确度。

Echo 声波移液系统最初由 Labcyte 开发,现已成为贝克曼库尔特自动化液体处理产品组合的关键组成部分。Echo 移液系统结合创新的 声波液滴喷射(ADE)技术,为科学家开展高通量实验带来开创性变革,广泛应用于药物发现、样品管理、合成生物学、基因组学、蛋白质组学和功能筛选等工作流。

Echo 声波移液系统关键优势

- Echo 声波移液系统支持低至 2.5 纳升级(nL)液体的精准转移,体积偏差小于 10%,移液 CV 值低于 8%

- 支持直接稀释化合物,避免了连续稀释法沿稀释曲线传递误差的风险,从而显著提高数据质量

Echo 声波移液系统利用声能非接触式移取不同类型液体,与传统移液器相比,无需吸头,无样本残留及交叉污染风险。

- 快速转移液体,每秒高达 700 份液滴。

- 声能转换器和目标板同时移动,实现任意孔间精准移液。/li>

- 无需耗时更换吸头,节省宝贵时间。

超微量反应体系,显著降低成本:

- 采用全声学检测就绪板(Acoustic Assay-Ready Plate, ARP)工作流,每年可节省 91% 化合物和 8000 L DMSO1

- 样品用量从数百千克级微量化至毫克级:仅需约7mg 构建模块和约20mg 溶剂,单次运行可合成 1536 种新化合物2

1 Green CP, Spencer PA, Sarda S. Drug Discov Today. 2021. 26(1):5–9. doi: 10.1016/j.drudis.2020.09.032.

2 Gao L et al. Green Chem. 2023. 25(4):1380-1394. doi: 10.1039/d2gc04312b.

- 动态液体分析(DFA)技术根据液体特性实时智能调节移液参数,确保对不同类型液体均能保持稳定的移液性能

- 支持复杂的组合式移液、多源样本 Pooling 和高通量筛选

- 适用于多种应用场景和实验流程

- 支持无缝整合 Access 系统和其他仪器

Echo 声波移液系统特点:

- 塑料制品总体用量锐减 87%,同时节省 72% 的 NGS 制备和测序成本3

- 采用声学液体处理技术,通过可重复使用的声学样品管/微孔板实现无接触移液,彻底消除吸头消耗。经实践验证,IDT 公司部署 Echo 声波移液系统后,每年可减少 逾3500 万支一次性吸头消耗。4

3 Torkamaneh D et al. Front Genet. 2020. 11:67. doi: 10.3389/fgene.2020.00067.

4 http://www.linkedin.com/pulse/reducing-plastic-pollution-one-tip-time-tom-speedy-jpvpe

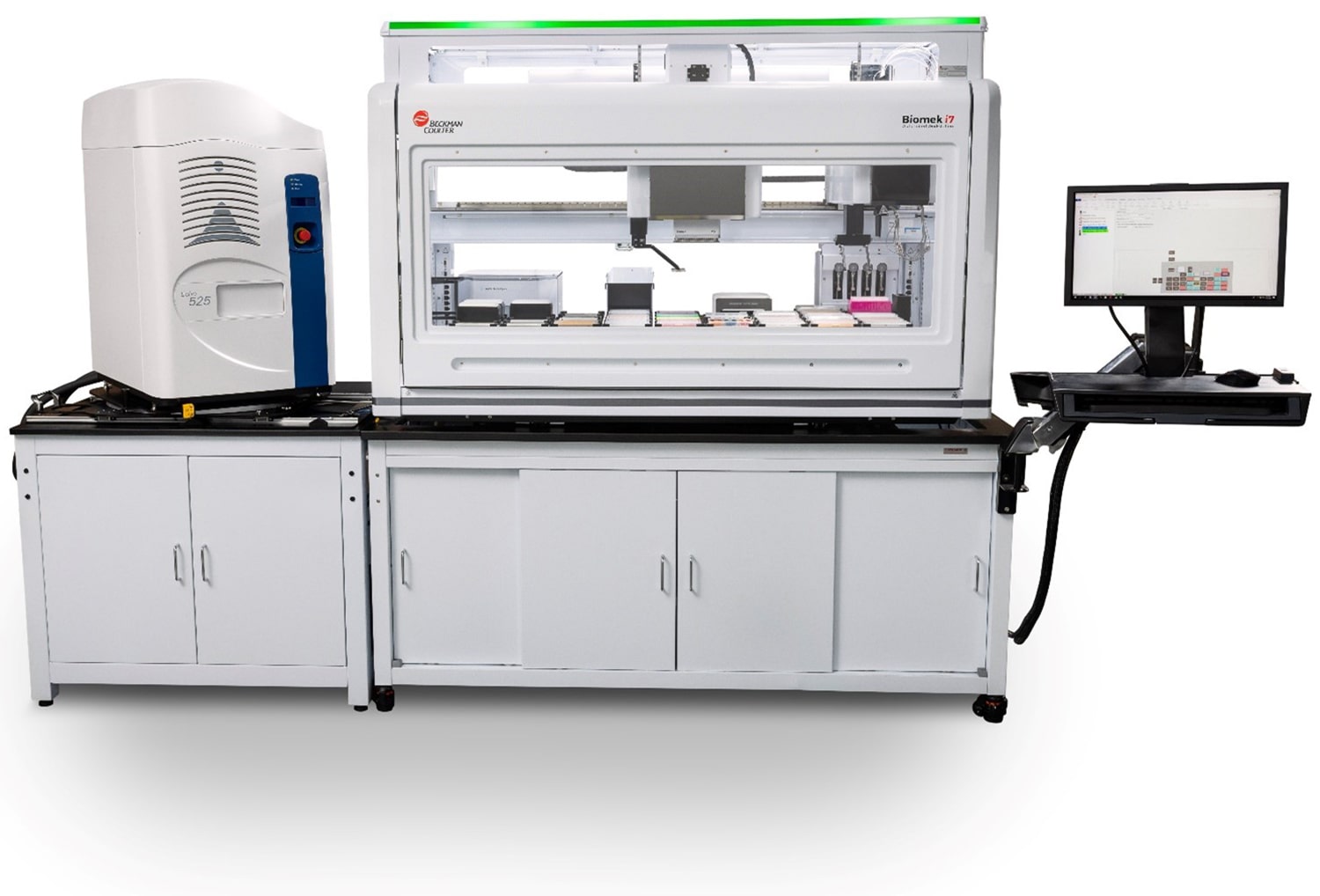

基于 Echo 的实验室自动化定制解决方案

众所周知,多数实验室任务已不仅限于任意孔间移液的简单应用。我们为您提供所有核心必备组件,助您基于 Echo 声波移液系统打造全流程自动化无人值守系统,按需定制复杂的工作流程:

- Access Solutions Group – 专注提供创新解决方案的专业团队,已为广大客户提供数千个实验室自动化定制解决方案

- 超 30 年自动化液体处理和机器人系统专业知识,携手 77 家供应商,提供超 400 个设备驱动程序

- 积极维护 233 个设备驱动程序 ,确保即时有效

- 丰富的软件工具,轻松实现自动化调度、数据管理和实验室编排

- 将您的 Echo 应用方案无缝集成至我们的调度软件中,无需重写应用程序

常见问题解答

这是一款无需吸头的非接触式声波移液系统,利用声能实现纳升级液体的任意孔间快速、精准、无接触式液体转移。点击了解 Echo 仪器声波微滴喷射(ADE)技术 详细信息。

Echo 声波移液系统无需用户校准,安装后即可运行。Echo 移液系统通过动态液体分析技术实时调整移液参数,以适应不断变化的液体类型(如 DMSO 溶液的水合状态及源孔中不同样品体积)。

Echo Qualified 微孔板 和 储液槽 可作为实验室源耗材使用。多数符合 ANSI/SLAS 1-2004 国际标准的微孔板(裙边高度<16mm)均可作为目标耗材使用。非标耗材(如微流控芯片、玻片),需搭配专用适配器使用(例如微流控芯片固定架、玻片承载框)。

不会!声波微滴喷射(ADE)技术使用声波形成流体堆,随后在目标孔内进行纳升级喷射。移液过程非常温和:我们的制药、生物技术和生物铸造厂客户经常使用该仪器转移核酸和抗体等生物制剂。研究人员已使用该技术实现 iPS 细胞(iPSC)等敏感细胞的成功转移。5

5 Gérard A at al. Nat Biotechnol. 2020. 38(6):715-721. doi: 10.1038/s41587-020-0466-7

为了协助您选择最契合当前和未来需求的解决方案,我们需要详细了解您的工作流程。请填写此表格获取满意答复。

Labcyte 还是贝克曼库尔特生命科学? Echo 仪器最初由 Labcyte 公司开发和制造。2019 年,Labcyte 成为贝克曼库尔特旗下公司。

设备正式名称为 Echo 声波移液系统,但也被称为声学分液器、声波移液器......声学惊人促进者。最后一个名称略显突兀,但凸显了我们创新技术的变革性。

更多其他问题?联系我们.

其他相关产品

These products are not intended or validated for use in the diagnosis of disease or other conditions.

ECHO is a trademark or registered trademark of Labcyte Inc. in the United States and other countries. Labcyte is a Beckman Coulter company. All other trademarks are the property of their respective owners.