使用MET ONE 3400+ 进行 ISO 14644-3 洁净室自净时间测试

引言

ISO 14644-3标准 B12 节描述了一种测试方法,用于评估洁净室及相关受控环境内气溶胶微粒从某一给定浓度的恢复能力。针对该方法所要求的测试微粒浓度水平,目前还存在一定的混淆。本应用指南将带您回顾标准检测方法,并就“检测浓度(Challenge)”和“目标洁净度等级(Target Cleanliness Level)”的选择提供指导。应注意,检测浓度不应过高,以避免引发“残留物污染”风险。

洁净室污染物控制工程师、微生物学家和制药设施管理人员普遍熟知 ISO 14644-1 中的“洁净室及相关受控环境”标准。ISO 14644-1 标准主要围绕空气洁净度等级(图 1),其中规定了不同粒径微粒的最大浓度限值。

| Class | Maximum particles / m3 | FED STD 209E equivalent |

|||||

| ≥ 0.1 μm | ≥ 0.2 μm | ≥ 0.3 μm | ≥ 0.5 μm | ≥ 1 μm | ≥ 5 μm | ||

| ISO 1 | 10 | 2 | |||||

| ISO 2 | 100 | 24 | 10 | 4 | |||

| ISO 3 | 1 000 | 237 | 102 | 35 | 8 | Class 1 | |

| ISO 4 | 10 000 | 2 370 | 1 020 | 352 | 83 | Class 10 | |

| ISO 5 | 100 000 | 23 700 | 10 200 | 3 520 | 832 | 29 | Class 100 |

| ISO 6 | 1 000 000 | 237 000 | 102000 | 35 200 | 8 320 | 293 | Class 1 000 |

| ISO 7 | 352 000 | 83 200 | 2 930 | Class 10 000 | |||

| ISO 8 | 3 520 000 | 832 000 | 29 300 | Class 100 000 | |||

| ISO 9 | 35 200 000 | 8 320 000 | 293 000 | Room air | |||

图1. ISO 14644-1 洁净度限值

这些静态限值通常基于以下三种状态之一进行考量:空态(as-built)、静态(at-rest)和“动态(operational)”。评估洁净室性能特性的关键特征之一是洁净室过滤系统能否动态去除空气中的微粒。ISO 14644-3 标准B12 节对检测方法进行了说明,即通过注入指定浓度的气溶胶,随后检测恢复时间,以评估洁净室的自净性能。

洁净室自净时间检测

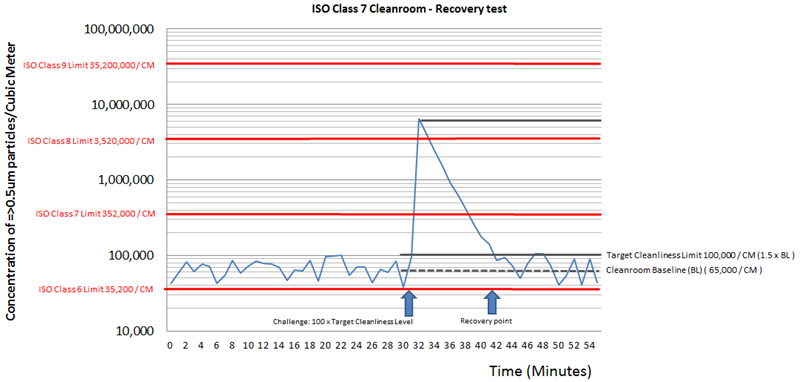

该检测旨在明确洁净室从检测浓度恢复至目标洁净度等级所需时间。ISO 14644-3 文件建议,自净时间检测仅应在安装非单向流系统且洁净室设施处于空态或静态环境的洁净室中进行,不建议在动态环境中进行该项检测。此外,不建议在 ISO 8 级或 ISO 9 级环境中进行该项检测,因为针对此类环境的检测浓度普遍过高。该标准还强调,当采用人工气溶胶的方法检测洁净室自净时间时,应避免洁净室设施残留物污染。特别是针对 ISO 7 级洁净室或具备高背景微粒数或基线水平的洁净室进行自净检测时,这一点尤为关键。因为自净时间检测要求按照高于“目标洁净度等级”100 倍的气溶胶浓度设定检测浓度。图 2 为在 ISO 7 级洁净室中进行的自净时间检测数据。如标准所述,微粒测量在微粒浓度衰减以指数衰减表示的时间范围内进行,该衰减在半对数图上以直线表示。请注意,微粒浓度以对数刻度绘制在纵坐标上,时间值以线性刻度绘制在横坐标上。

图 2. 在 ISO 7 级洁净室中进行的自净时间检测

在洁净室中设置并运行空气颗粒计数器后,应建立洁净室的背景值或“基线”标准。在上文示例中,经计算,该 ISO 7 级洁净室的平均基线标准为:每立方米 ≥0.5um 的微粒数为65,000 颗。

目标洁净度等级

关于如何选择目标洁净度等级,目前还存在理解误区。许多检测人员将其错误地理解为等级限值(Class Limit),例如在 ISO 7 级洁净室中,微粒浓度等级限值为每立方米 ≥0.5um 微粒最大允许数为 352,000 颗。因错误理解导致检测人员计算得出该洁净室所需的检测浓度为该气溶胶浓度限值的 100 倍,即每立方米 35,200,000 个粒子。对于洁净室而言,如此高的气溶胶浓度相当于办公楼和住宅典型环境下的微粒浓度。然而,ISO 14644-3 标准旨在检测洁净室在高于基线标准 100 倍气溶胶浓度下的自净时间,同时将“洁净室设施残留物污染”风险降至最低。选择尽可能低的目标洁净度等级是完全可以接受和可行的。理论上而言,可选择洁净室微粒基线标准作为目标洁净度等级。然而,应考虑到,在检测过程中,检测人员的存在可能使空气中的微粒浓度略微升高。因此,建议设置目标洁净度等级时应略高于微粒浓度基线,但不应超过微粒基线标准的 1.5 倍。通过这种方式,可在有效进行自净时间检测的同时,避免因微粒浓度过高而产生损害洁净室的风险。

讨论

ISO 14644-3 标准提供了两种洁净室自净计算方法,100:1自净时间检测法,是一种简单的方法,可直接测量洁净室从高于目标洁净度等级 100 倍的气溶胶检测浓度条件下,完成自净所需时间。在本文示例中,自净时间为 12 分钟。100:1 直接自净检测法是最简单有效的方法。在 ISO 14644-3 文件中,也将该方法列为首选方法。在无法将初始浓度设置为高于目标洁净度等级 100 倍的情况下,该标准提供了一种替代方法,即“通过自净率进行评估”。这种替代方法适用于在半对数图上可识别出直线段,且可在直线段上识别足够数量(至少 5 个)的连续测量对,并可基于这些数据应用所描述的斜率计算。该辅助方法仅可作为替代方法,应尽可能避免使用。

结论和建议

在 ISO 14644-3自净时间的检测时, ISO洁净室经常非必要地使用过高微粒浓度,特别是针对 ISO 7 级洁净室,检测人员通常不恰当地设置洁净室检测浓度,甚至超过了 ISO 9 级洁净室的限度,甚至空气中的微粒浓度相当于普通办公室或住宅环境中的浓度。

在本应用指南提供的示例中,ISO 7 级洁净室的微粒检测浓度略高于 ISO 8 级限值,如此以来即可根据标准中的指南要求将“洁净室设施残留物污染”风险降至最低。

通过充分评估洁净室基线微粒水平和适当的目标洁净度等级,可应用相对简单的 100:1 自净时间检测方法,从而避免对洁净室造成污染。

参考文献

- ISO 14644-1 Cleanrooms and associated controlled environments – Part 1: Classification of air cleanliness

- ISO 14644-3 Cleanrooms and associated controlled environments – Part 3: Test methods. First Edition 2005-12-15

Helpful Links

Environmental Monitoring

MET ONE 3400+ Air Particle Counter

GMP Cleanroom Compliance

Video Gallery

Industry Standards

Quality Control for GMP Manufacturing

ISO 21501

ISO 14644

21 CFR Part 11